Wood

The following documents introduces the types of wood veneer and base materials that are most commonly used in display showcases and interior fixtures. You'll get an understanding of different cuts of woods and how they can vary from one piece to another, also the base materis for wood veneer. If you have any questions regarding a specific materials listed or have an alternative design you'd like to have quoted, please contact us for more information.

Veneers and Layup options

Practised by furniture makers for centuries, veneer pattern matching is a real celebration of skill achieved by matching veneers to create unique patterns.

With such a vast number of timber species, methods of slicing and layup patterns to choose from, a helpful approach is to break the design choices down into the following steps.

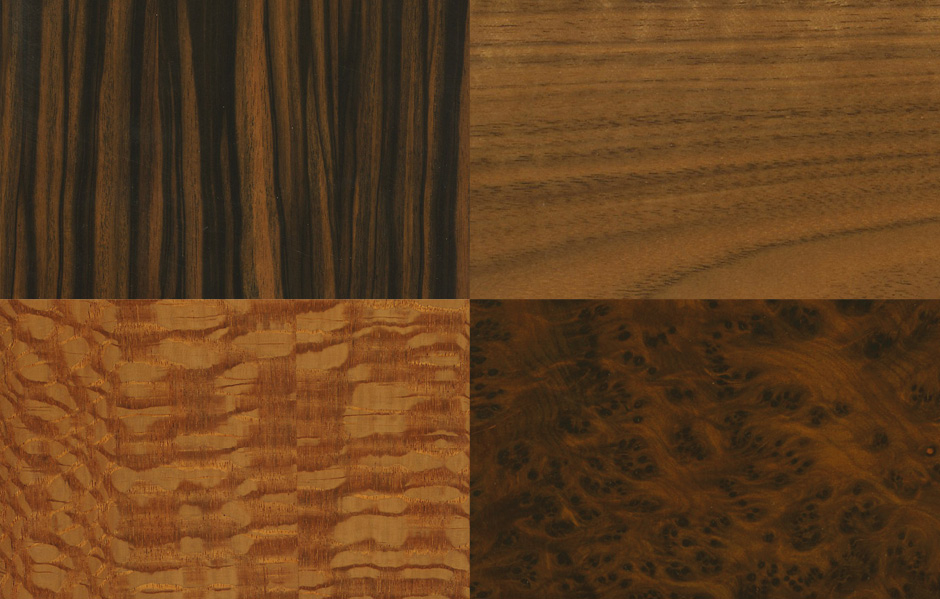

Timber species

The choice of what timber species to use is one often dictated by design direction and budget, ranging from a generic wood such as Birch to Ashwood with more unusual options available such as Macassar Ebony, American Oak and various wood burls most commonly walnut.

Budget inevitably introduces some constraints, but there are also ways to add value through both colour staining and the choice of veneer layup.

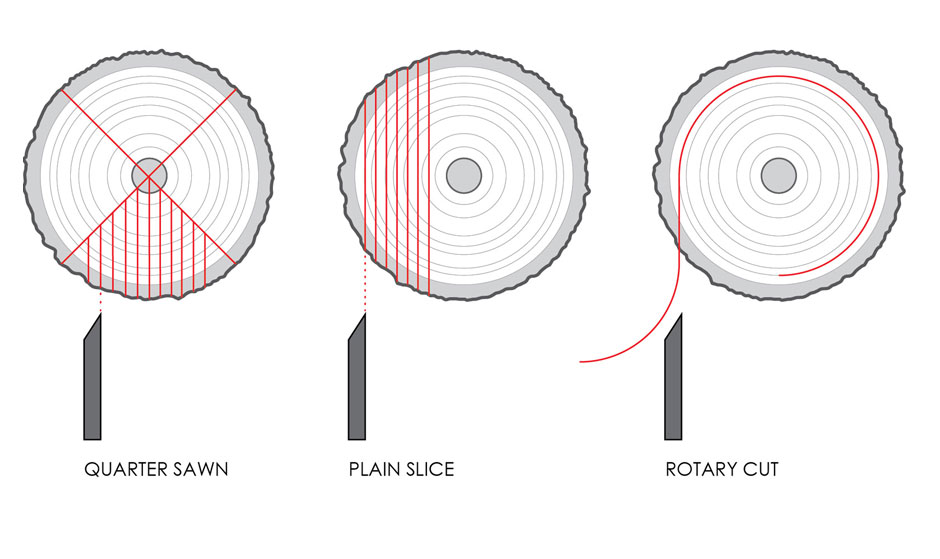

Slicing methods

This refers to the process of slicing from larger lumber planks or half logs, using knives that move backwards and forward – like slicing a loaf of bread. This method best shows figuring of wood e.g. on walnut.

QTR Cut: This method of slicing is perpendicular to the annual growth rings of the tree, which creates a very linear grain appearance the result of which is a stripy veneer. Plain slice (Flat cut): This is produced from the portion of the tree just below the point where it forks into other branches, which creates a variety of flame figures. Rotary Cut: The log is turned in a circular motion against a knife peeling off a continuous thin sheet of wood veneer. This is the most effectual method of producing veneer, resulting in the highest yield.

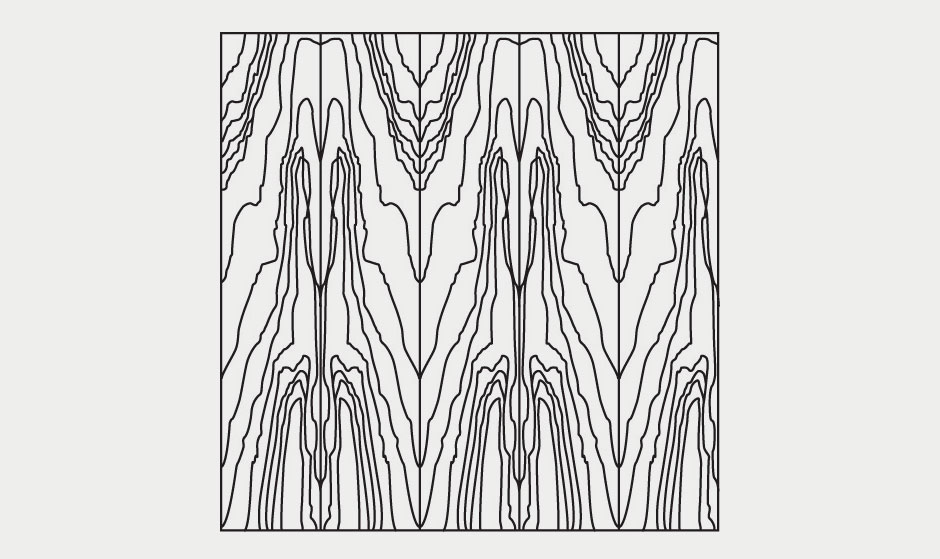

Book Matching

Successive veneer leaves are laid next to one another which appear to have been turned like pages of a book. Since the reverse side of one leaf is the mirror image of the succeeding leaf, the result is a series of pairs. The craftsperson must choose the veneer leaves carefully to ensure that when 2 pieces are butted up against each that the grain matches.

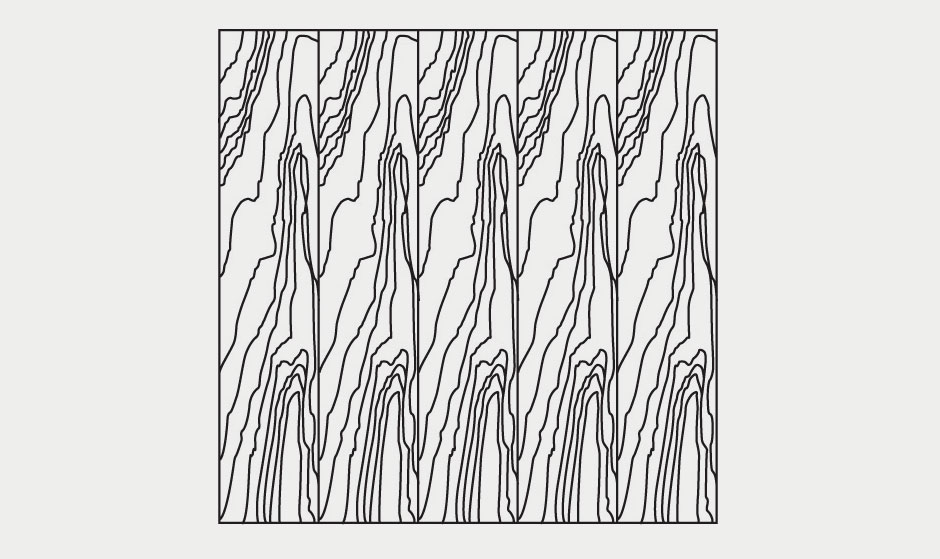

Often used with QTR cut veneers, this is the process in which a sequence of matching veneer leaves are laid in consecutive sheets, creating a continuous display of uniformity where the joints are less obvious.

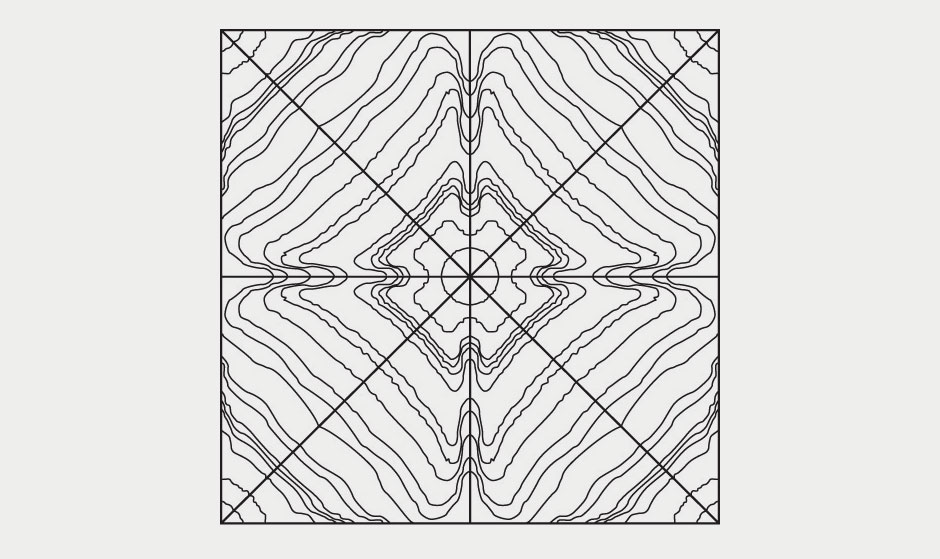

Ideal for enhancing the appearance of a circular table top, this is arguably one of the most spectacular layups that feed out from the centre like a section of a pie chart. If laid well it can even resemble a solid wood like a section of tree trunk.

MDF and PLYWOOD

While it's hard to match the natural beauty of solid wood, it's an undeniably pricey option. Fortunately, for many projects, the two main substitutes medium density fiberboard (MDF) and plywood are less expensive, yet perform just as well or better than solid wood for a wide range of projects, including furniture, cabinets, shelves, and decorative accents such as wainscoting.

MDF starts off with hardwood and softwood fibers, which are glued together with various resins, and then subjected to high heat and pressure to form panels. Plywood undergoes a similar process, but instead of wood fibers, starts off with very thin layers of wood from peeler logs, and the different thicknesses and grades - the higher the grade, the higher the price,in general, MDF costs less than plywood.

Plywood and MDF are useful materials for many DIY projects around the home. As a general rule, however, MDF is the better choice for indoor furniture or decorative use, especially if you want to cut intricately carved trim or designs, and plan on painting the finished project. Plywood is excellent for outdoor use, for framing walls or building floors and for projects that require a curve.

Fire Retardant Board

MDF and Plywood is one of the most widely used wood products in the building industry. However, MDF and plywood is still subject to catching fire. But with the use of fire retardants, MDF and plywood can become resistant to fire too.

Fire retardant board is created by applying a chemical preservative to the MDF and plywood. This chemical preservative helps the MDF and plywood withstand heat and resist burning. If a fire is to occur, the preservative will help the fire retardant MDF and plywood burn more slowly than untreated wood.

It also provides more protection against bugs and mold than untreated.

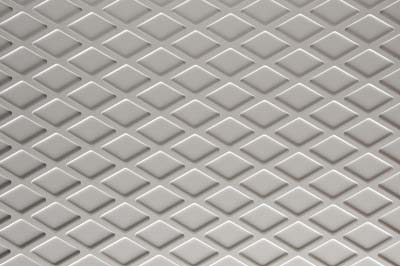

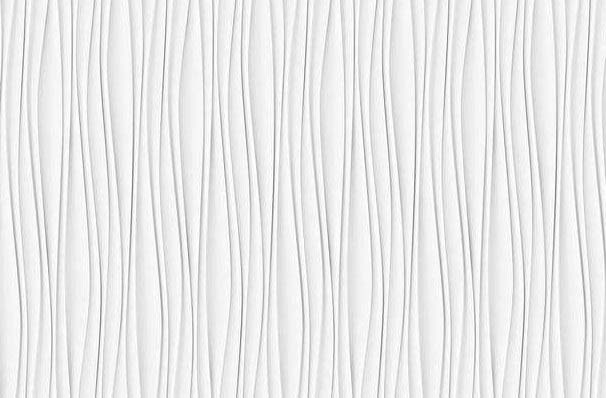

Alouette Panels

The Alouette material consists out of 3 collections, the Basic, the Wave and the Sand collection. Each collection contains its own structures which are available in 100 colours. By using CNC cutters it's possible to program larger surfaces and divide these surfaces afterwards, making it possible to create continuing patterns over different panels.

The panels are manufactured out of carved MDF with a white coating. The back of the MDF is protected with a melamin sheet to prevent bending caused by humidity. The basic panel always have a white coating, from this basic the client can change the surface he chooses either by using standard water based paints.